RSBJ 1650 (XAGA 1650)

General

1.High performance heat shrinkable closure for unpressurized applications

2.Widely used in overhead erection of pipeline,the splice closure of buried cable;able to work under an environment of -30 to +90C for a long term.

3.The heat shrinkable sleeve has a Aluminium layer and get a super moisture-resistant performance

4.It is of super composite fiber structure and secondary sealing, featured by high mechanical strength, strong tearresistant, and strong shrinkage and excellent resistance to weathering.

5.Super Sleeve sealing gel material is composed of several layers of specially blended polymers, adhesives and fiber-reinforcing layer. The fiber-reinforcing layer provides excellent mechanical strength and eliminates the propagation of localized damage that can result from overheating or other errors in installation. Once the closure sleeve has been installed, the composite design of the Super Sleeve sealing gel material provides superior mechanical protection from forces such as impact, abrasion, UV light, and atmospheric contamination.

6.The closure bears an excellent sealing performance under both high and low temperature as well as normal temperature; The softening point can be up to 130 degrees centigrade, suitable for the area of high ambient temperature.

7.Range of closures to suit all cable sizes

8.Simple and easy to install

9.Unlimited shelf life

More information about the heat shrinkable sleeve: It is composed of 5 layers

List of Assembly Parts

1st layer:polyethylene film

2nd layer:High Density Web(heat shrinkable thread+glass fiber )

3rd layer:polyethylene film

4th layer:Aluminium film(only for RSBJ/super moisture-resistant performance)

5th layer:Hot-melt Adhesive

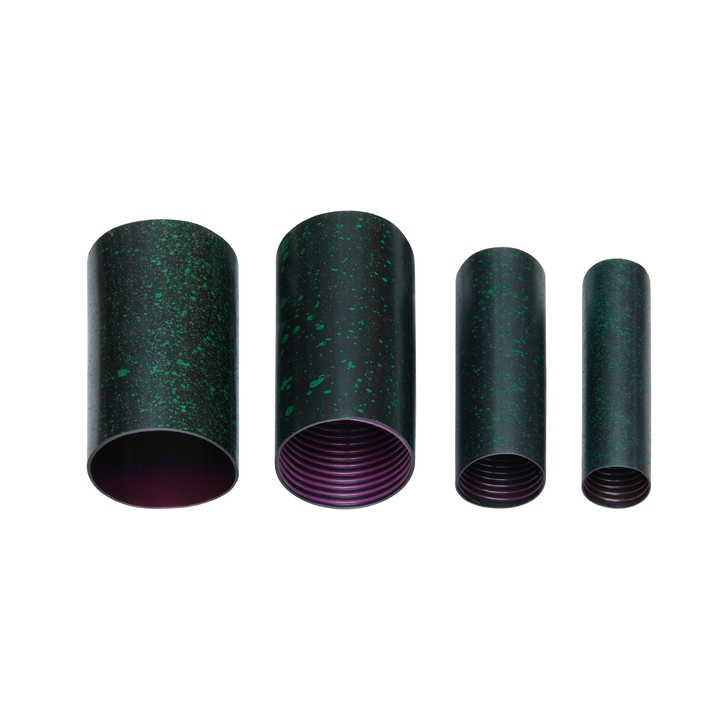

Heat shrinkable sleeve

Carboard canister

Flexible stainless steel channels (stainless steel)

Branch off clip (duralumin+Hot-melt Adhesive)

Nylon binding strip (Nylon)

Abrasive strip (cloth covered with powdered emery)

PVC adhesive tape (PVC)

Reinforced PE tape

Plactic net

Cleaning clother (absolute ethyl alcohol+non-woven fabrics)

Shield continuity wire(power line+copper clip)

Aluminium cable tape (Aluminium)

Aluminium closing strip(Aluminium)

Technical Specifications of Heat Shrinkable Splice Closure

RSBJ 1650 (XAGA 1650) for Non-pressurized cables

Use Table 1 to select the appropriate size XAGA 1650 buried splice closure kit.

| CLOSURE SIZE | SPLICE OPENING (INCHES) | MIN. CABLE DIA- METER* (INCHES) | MAX. CABLE DIA-METER (INCHES) | APPROX. CABLE RANGE** (PAIRS) |

| 1650 S | 12.0 | 0.35 | 1.10 | 6-25 |

| 1650 A | 12.0 | 0.48 | 2.20 | 25-100 |

| 1650 A2 | 21.0 | 0.48 | 2.20 | 25-200 |

| 1650 AA | 9.0 | 0.48 | 2.20 | 25-100 |

| 1650 B | 12.0 | 1.10 | 3.75 | 100-300 |

| 1650 B2 | 21.0 | 1.10 | 3.75 | 200-400 |

| 1650 C2 | 21.0 | 1.85 | 5.30 | 600-900 |

| 1650 D2 | 24.0 | 2.00 | 7.10 | 900-2400 |

| 1650 A4 | 37.0 | 0.48 | 2.20 | 25-400 |

| 1650 B4 | 37.0 | 1.10 | 3.75 | 200-600 |

| 1650 C4 | 37.0 | 1.85 | 5.30 | 600-1800 |

| 1650 D4 | 37.0 | 2.00 | 7.10 | 900-3600 |

* Cable range and encapsulant required will vary depending upon cable type, gauge, connector type, and splice configuration.** If cable diameter is less than recommended, an End Plug Rod can be used asa shim to increase the effective diameter.

Related products

-

Phone

-

E-mail

-

Whatsapp

-

Top