Dome Type Vertical Fiber Closure/Enclosure GJS03-M8AX-RS

Specifications

| Model: | GJS03-M8AX-RS-144 | ||

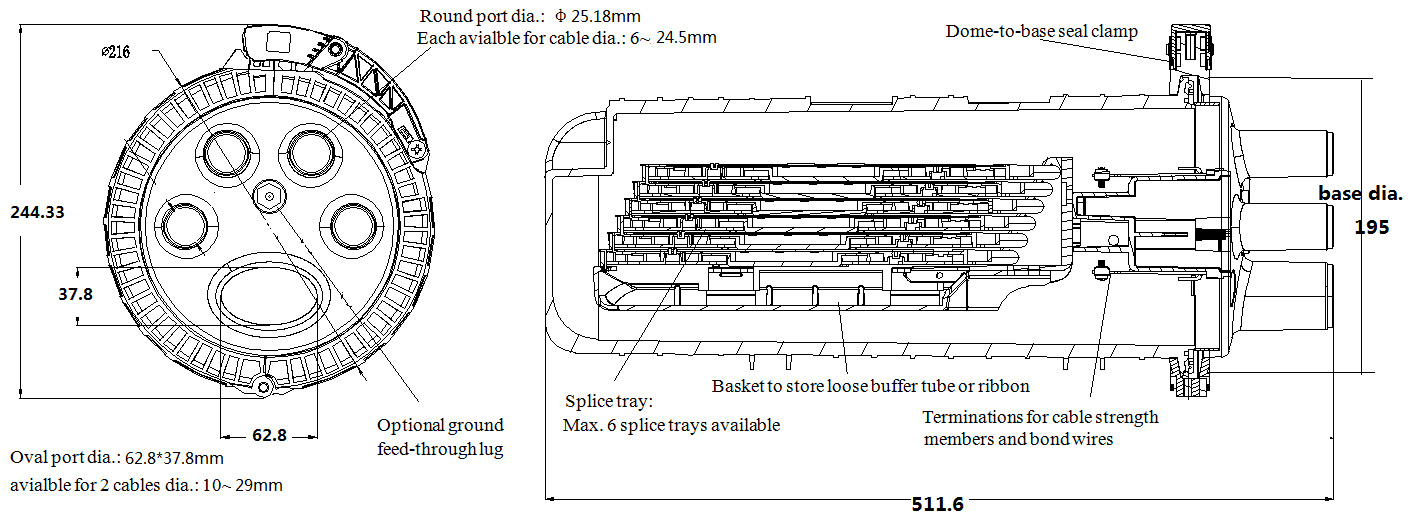

| Size:With clamp biggest outer dia. | 511.6*244.3 mm | Raw material | Dome,clamp: modified PP, Base:Nylon +GF Tray: ABS Metal parts:Stainless steel |

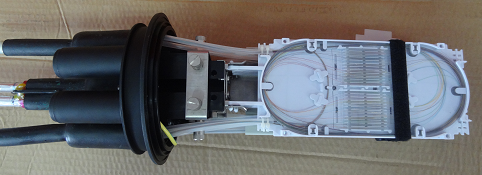

| Entry ports number: | 1 oval port,4 round ports | Available cable dia. | Oval port:available for 2 pcs, 10~29mm cables Round ports:Each available for 1pc 6-24.5mm cable |

| Max. tray number | 6 trays | Base sealing method | Heat-shrink |

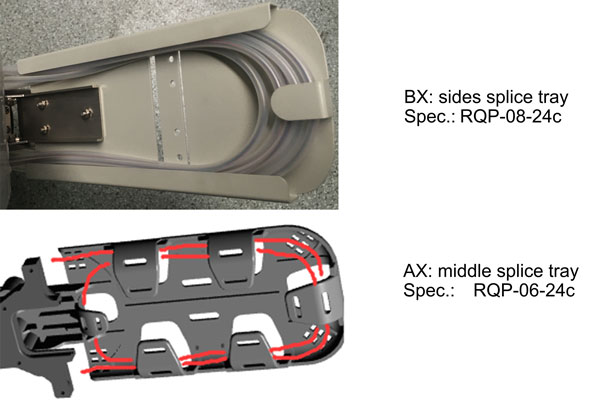

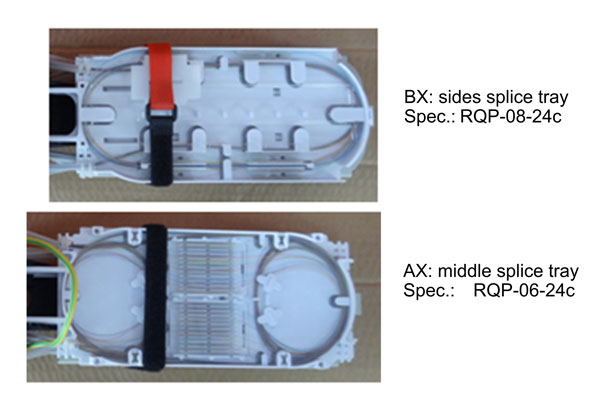

| Tray capacity: | 24F | Applications: | Aerial, directly buried, Wall/ pole mounting |

| Max. closure splice capacity | 144 F | IP grade | 68 |

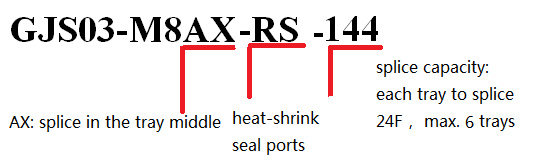

Order Guidance

Exterior Structure Diagram

Technical Parameter

1. Working Temperature: -40 degrees centigrade~+65 degrees centigrade

2. Atmospheric Pressure: 62~106Kpa

3. Axial Tension: >1000N/1min

4. Flatten Resistance: 2000N/100 mm (1min)

5. Insulation resistance: >2*104MΩ

6. Voltage Strength: 15KV(DC)/1min, no arc over or breakdown

7. Temperature recycle: under -40℃~+65℃,with 60(+5)Kpa inner pressure, in 10cycles; Inner pressure shall decrease less than 5 Kpa when closure turn to normal temperature.

8. Durability:25 years

Installation Guidance

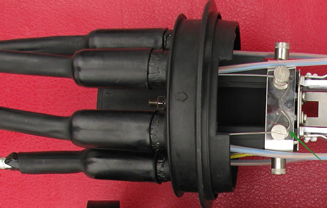

1. Cut the ports to guide the cable

2. Put the cable through the heat-shrink tube

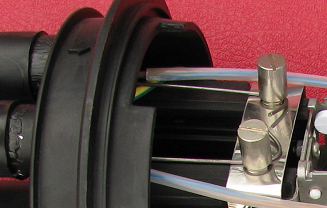

3. Remove the sheath of the cable and clean it. Cut the strengthen member to 5cm length. Put it through the attach screws and bend it to fix on the screw. Then tighten the screw.

4. Remove the loose tube of the cable and clean the bare fibers. Put them through the transparent PE tube. Using PVC tape to wrap the end of the PE tube and cable.

5. Wind the excessive loose fibers in suitable cycles and put them in the storage basket.

6. Coiling the fibers in the splice trays from the bottom tray to the top one as the picture above. Fusion the joints and shrink the protective tubes and fix them in the tray. Then cover the tray lid.

7. Use the Velcro strip to bind the trays.

8.Using abrasive strip to rough the surface of the cable sheath and ports slightly.

9. Clean the cable surface and ports

10. Move the heat-shrink tube to cover the base port and the cable. Mark the tube end on the cable and stick the aluminum film on it. The blue line of the film shall at the same position of the marked place. ( Edge which close to the blue line shall be in the tube. Other side out of the tube.) Using blunt tool to smoooth the film tightly stick to the cable. Using heat-gun to heat the heat-shrink tube in the direction of the red arrow slowly. (If to guide 2 cables in the oval port, use branch off clips to separate the cables , heat the branch off clip to seal the space meanwhile.)

11. heat the round ports following the same step as the oval port

12. close the closure with the clamp.

13.Choose the suitable mounting kits for different installation environment.

Features

This closure can be used in duct, buried, overhead..etc

High quality impact material.pp and internal is PP,ABS

Designed for ftth with adapter if needed.

Fiber storage with big basket

Modular fiber management system

Cable diameter range: 8~20 mm

Sealing way of cables:Mechanical seaing by silicon rubber

IP rating is IP68

Related products

-

Phone

-

E-mail

-

Whatsapp

-

Top